How to cut plexiglass with a table saw? lets find the answer. Plexiglass, also known as acrylic glass or Perspex, is a versatile material that is widely used in various industrial, commercial, and DIY projects. It is transparent, lightweight, shatter-resistant, and thermoplastic, which makes it a popular substitute for glass.

However, cutting plexiglass can be intimidating, especially for novice DIYers and woodworkers. Using a table saw can be a great choice because it offers precision, speed, and clean cuts that are not easily achieved with other tools.

However, it is essential to use the right blade, feed speed, and cutting technique to avoid damaging the plexiglass or injuring yourself.

In this blog post, we will explore the step-by-step process of cutting plexiglass with a table saw, including selecting the appropriate blade, adjusting the saw settings, securing the workpiece, and making the cut. We will also provide some tips and tricks to help you achieve a perfect cut every time.

Ensure the plexiglass is firmly secured to the table saw.

When cutting plexiglass with a table saw, it is important to ensure that the plexiglass is firmly secured to the table saw. This is to prevent the plexiglass from shifting during the cutting process, potentially leading to inaccuracies, breakage or injury.

To securely attach the plexiglass to the table saw, use clamps or other secure fasteners to hold it in place.

The plexiglass should be positioned in such a way that the blade of the saw will cut the material without any interference or resistance.

Before beginning the cutting process, double check that the plexiglass is properly attached and will not move during the operation.

This simple step can help ensure a safe and accurate cutting process when using a table saw to cut plexiglass.

Use a sharp carbide saw blade for the best results.

If you plan to use a table saw to cut plexiglass, it’s important to use a sharp carbide saw blade to achieve the best results. Carbide blades have small, sharp teeth that are perfectly suited for cutting through plexiglass without chipping or cracking it.

It’s also essential to ensure that the blade is securely fastened in the saw and it’s aligned correctly. When cutting plexiglass with a table saw, it’s important to maintain a steady pace and not force the material through the blade.

This can cause the plexiglass to splinter or even crack, and ruin your project. By following these guidelines, you can properly cut plexiglass with a saw and achieve the desired results.

Adjust the blade height to slightly higher than the thickness of the plexiglass.

If you are planning on cutting plexiglass with a table saw, it is essential to ensure that the blade is set at the correct height. Adjusting the blade height to slightly higher than the thickness of the plexiglass is crucial for achieving a clean and precise cut.

Plexiglass is a thermoplastic material that is more forgiving than glass and easier to work with, but it can also break or melt if exposed to too much heat or pressure.

To avoid such issues, it is vital to take into account the thickness of the plexiglass before cutting, and then adjust your blade height accordingly.

This attention to detail is critical when attempting to achieve a smooth and successful cut without damaging the material.

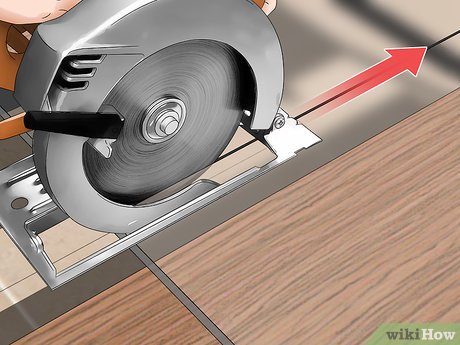

Slowly and steadily feed the plexiglass into the blade.

If you are planning on cutting plexiglass with a table saw, it is important to follow proper safety procedures to avoid any mishaps or accidents. One important step in this process is to slowly and steadily feed the plexiglass into the blade.

Doing so will ensure that the blade cuts through the material smoothly and avoids any cracking or breaking of the plexiglass.

Additionally, maintaining a consistent feed rate will help to produce a cleaner cut and improve the overall quality of the finished product.

Care and attention to detail during the cutting process will not only make the process easier, but it will also help to ensure the ultimate success of the project.

Use a push stick or other safety device to keep your hands away from the blade.

When cutting plexiglass with a table saw, safety precautions are essential to preventing accidents and injury. One of these precautions is the use of a push stick or other safety device to keep your hands away from the saw blade.

Using your hands to guide the plexiglass through the saw can be dangerous, as this increases the risk of contact with the blade. A push stick is a simple tool that allows you to apply pressure to the plexiglass while keeping your hands a safe distance from the blade.

In addition to push sticks, there are other safety devices available that can be used to achieve the same goal. It is important to remember that any safety device used should be appropriate for the size of the material being cut and the type of cut being made.

Take the time to familiarize yourself with the proper use of these devices before attempting to cut plexiglass with a table saw.

Avoid applying too much pressure or force as this can cause the plexiglass to crack.

Using a table saw is one of the most efficient ways of cutting plexiglass. However, it is crucial to take the necessary precautions as the material is brittle and prone to cracking. One important tip to keep in mind is to avoid applying too much pressure or force while cutting the plexiglass.

Excessive pressure can cause the material to crack, rendering the entire piece useless. Furthermore, the crack may also compromise the structural integrity of the plexiglass, making it a safety hazard.

Therefore, it is recommended to maintain a steady, firm grip on the material while gently guiding it through the blade. This will ensure clean and precise cuts without causing any damage to the plexiglass.

Keep the blade moving at a steady speed throughout the cut.

If you are looking to cut plexiglass with a table saw, it is important to keep the blade moving at a steady speed throughout the cut. This is essential to achieving a clean cut with a smooth edge.

Keeping a consistent speed will prevent the blade from heating up and melting the plexiglass, which can result in rough edges and deformities in the material. It is also important to keep the blade lubricated during the cutting process, to reduce friction and prevent overheating.

By following this simple tip, you can achieve a precise and professional-looking cut on your plexiglass using a table saw.

Use a dust collector or vacuum to remove any debris or shavings.

When working with plexiglass, it is important to take the necessary precautions to avoid any accidents or damages to the material. One key step in the cutting process is to clean up any debris or shavings that may have accumulated around the working area. T

o achieve this, using a dust collector or vacuum is highly recommended. The high-speed spinning of the saw blade creates a significant amount of debris, and if left unnoticed, it can interfere with the cutting process and potentially affect the precision of the final cut.

Additionally, the debris can create a hazardous working environment for the operator, leading to possible injuries. Therefore, regularly clearing plexiglass shavings out of the way will not only guarantee a clean and accurate cut, but it will also ensure the safety of those working with the material.

Allow the blade to come to a complete stop before removing the cut piece of plexiglass.

When working with plexiglass, safety should be of paramount importance. One of the key safety guidelines to follow when using a table saw to cut plexiglass is to allow the blade to come to a complete stop before removing the cut piece.

Plexiglass can easily crack or shatter, which is why it’s crucial to avoid touching the cut piece until the blade has stopped moving entirely. If you need to make any adjustments or clean up scraps of material, use a scrap piece of wood or other tool to do so, instead of your hands.

Keeping these safety precautions in mind will help to ensure that your plexiglass cutting experience is both successful and safe.

Wear safety goggles and other protective gear to prevent injury.

When cutting plexiglass with a table saw, it is important to take precautions to prevent injury. One of the most important steps you can take is to wear safety goggles and other protective gear. Plexiglass can shatter or produce flying debris during cutting, which can potentially cause eye injuries or cuts.

Safety goggles can protect your eyes from any particles or splinters that may result from the cutting process. You should also consider using gloves and clothing that covers your skin, as well as a dust mask, to minimize the risk of injury.

Ensure that you are equipped with proper protection before you begin using a table saw to cut plexiglass.

In conclusion, cutting plexiglass with a table saw can be tricky but it is possible if you take the right precautions and use the correct tools. Remember to use a saw blade with fine teeth, maintain the correct blade height, and prevent the plexiglass from vibrating during the cut. With these tips, you can create clean, accurate cuts in plexiglass and accomplish your project with ease.