Fiberglass blades are widely used in various industries due to their lightweight, durability, and high-performance capabilities. However, to ensure their longevity and optimal performance, it’s essential to use them correctly. Whether you’re working with wind turbine blades, industrial equipment, or marine applications, this guide will walk you through the best practices for handling, maintaining, and using fiberglass blades effectively.

Understanding Fiberglass Blades

Before diving into usage tips, it’s important to understand what fiberglass blades are. Made from composite materials, fiberglass blades combine glass fibers with a resin matrix to create a lightweight yet strong structure. They are known for their corrosion resistance, thermal stability, and fatigue resistance, making them ideal for demanding applications.

Step-by-Step Guide to Using Fiberglass Blades

1. Inspect the Blade Before Use

Before using a fiberglass blade, conduct a thorough inspection to ensure it’s in good condition. Look for:

Cracks or chips on the surface

Signs of wear or damage

Proper alignment and balance

If you notice any issues, do not use the blade until it has been repaired or replaced. Damaged blades can compromise safety and performance.

2. Choose the Right Blade for the Job

Fiberglass blades come in various shapes and sizes, each designed for specific applications. For example:

Wind turbine blades are optimized for aerodynamic efficiency.

Industrial cutting blades are designed for precision and durability.

Marine propellers are built to withstand harsh water conditions.

Ensure you select the appropriate blade for your task to achieve the best results.

3. Handle with Care

Fiberglass blades are lightweight but can be fragile if mishandled. Follow these tips:

Always lift and carry the blade with both hands.

Avoid dropping or hitting the blade against hard surfaces.

Store the blade in a safe, dry place to prevent damage.

4. Install Correctly

Proper installation is crucial for the safe and effective use of fiberglass blades. Here’s how to do it:

Follow the manufacturer’s instructions for installation.

Use the recommended tools and hardware.

Ensure the blade is securely fastened and balanced to prevent vibrations or wobbling during operation.

5. Operate Within Recommended Limits

Fiberglass blades are designed to perform under specific conditions. To avoid damage:

Do not exceed the maximum speed or load capacity specified by the manufacturer.

Avoid using the blade in environments with extreme temperatures or corrosive substances unless it’s specifically designed for such conditions.

Monitor the blade during operation to ensure it’s functioning smoothly.

6. Maintain Regularly

Regular maintenance is key to extending the lifespan of fiberglass blades. Follow these maintenance tips:

Clean the blade after each use to remove dirt, debris, or residue.

Inspect the blade periodically for signs of wear or damage.

Lubricate moving parts as recommended by the manufacturer.

Replace the blade if it shows significant wear or damage.

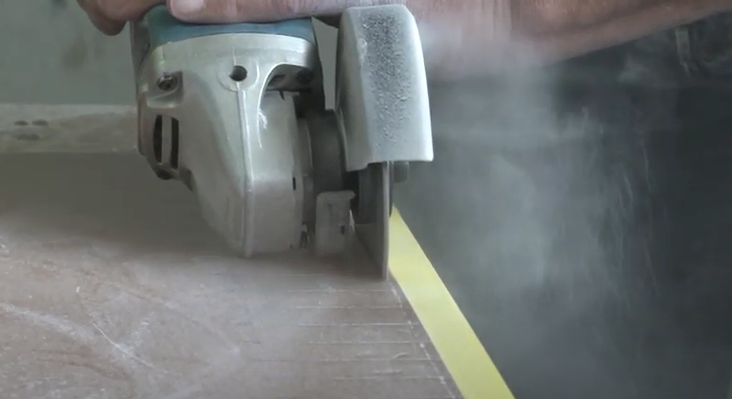

7. Ensure Safety During Use

Safety should always be a top priority when working with fiberglass blades. Here are some safety tips:

Wear protective gear, including gloves, goggles, and a mask, to protect against fiberglass particles.

Keep your work area clean and free of obstacles.

Never operate the blade without proper training or supervision.

Turn off and unplug equipment before inspecting or maintaining the blade.

Common Mistakes to Avoid

Overloading the Blade: Exceeding the blade’s capacity can lead to cracks or breakage.

Improper Storage: Storing the blade in a damp or uneven area can cause warping or damage.

Neglecting Maintenance: Skipping regular inspections and cleaning can reduce the blade’s lifespan.

Using Damaged Blades: Always replace damaged blades to avoid accidents and ensure optimal performance.

Applications of Fiberglass Blades

Fiberglass blades are used in a wide range of industries, including:

Wind Energy: Wind turbine blades harness wind power efficiently due to their aerodynamic design and lightweight properties.

Aerospace: Aircraft components benefit from the strength-to-weight ratio of fiberglass blades.

Marine: Boat propellers and other marine equipment rely on fiberglass blades for their corrosion resistance.

Industrial: Cutting and grinding tools use fiberglass blades for precision and durability.

Conclusion

Fiberglass blades are a versatile and high-performance solution for various applications, but their effectiveness depends on proper usage and maintenance. By following the guidelines outlined in this article, you can ensure the safe and efficient use of fiberglass blades, extending their lifespan and maximizing their performance.

Whether you’re working in renewable energy, aerospace, or industrial manufacturing, understanding how to properly use fiberglass blades is essential for achieving the best results. Remember to inspect, handle, install, and maintain your blades with care, and always prioritize safety during operation.

By adhering to these best practices, you can make the most of fiberglass blades’ unique properties and contribute to a safer, more efficient working environment.