When it comes to cutting fiberglass insulation, using the best blade for cutting fiberglass insulation is crucial for achieving clean, precise cuts while ensuring safety and efficiency. Fiberglass insulation is a common material used in construction, HVAC systems, and home improvement projects, but cutting it improperly can lead to uneven edges, material waste, and even health risks due to airborne fibers. In this comprehensive guide, we’ll explore the top blades for cutting fiberglass insulation, their features, and how to choose the right one for your needs. Whether you’re a DIY enthusiast or a professional contractor, this article will help you make an informed decision.

Why Choosing the Right Blade Matters

Fiberglass insulation is a lightweight yet durable material made of fine glass fibers. Cutting it requires a blade that can handle its unique properties without causing fraying, tearing, or excessive dust. Using the wrong blade can result in:

Uneven cuts: Poor-quality blades may leave jagged edges, making installation difficult.

Health hazards: Fiberglass particles can become airborne, posing respiratory risks.

Blade wear and tear: Inappropriate blades can dull quickly, increasing replacement costs.

The best blade for cutting fiberglass insulation ensures clean cuts, minimizes dust, and extends the blade’s lifespan, saving you time and money.

Top Blades for Cutting Fiberglass Insulation

Here are the best blades for cutting fiberglass insulation, based on performance, durability, and user reviews:

Carbide-Tipped Utility Knife Blades

Why it’s great: Carbide-tipped blades are extremely sharp and durable, making them ideal for clean cuts through fiberglass insulation.

Best for: Precision cutting and small-scale projects.

Popular brands: Stanley, Olfa, and Milwaukee.

Reciprocating Saw Blades with Fine Teeth

Why it’s great: Reciprocating saw blades with fine teeth (10-14 TPI) provide smooth, fast cuts through thick fiberglass insulation.

Best for: Large-scale projects and professional use.

Popular brands: Diablo, DeWalt, and Bosch.

Rotary Tool Cutting Wheels

Why it’s great: Rotary tools with fiberglass cutting wheels are perfect for detailed cuts and tight spaces.

Best for: DIY projects and intricate cuts.

Popular brands: Dremel, Makita, and Ryobi.

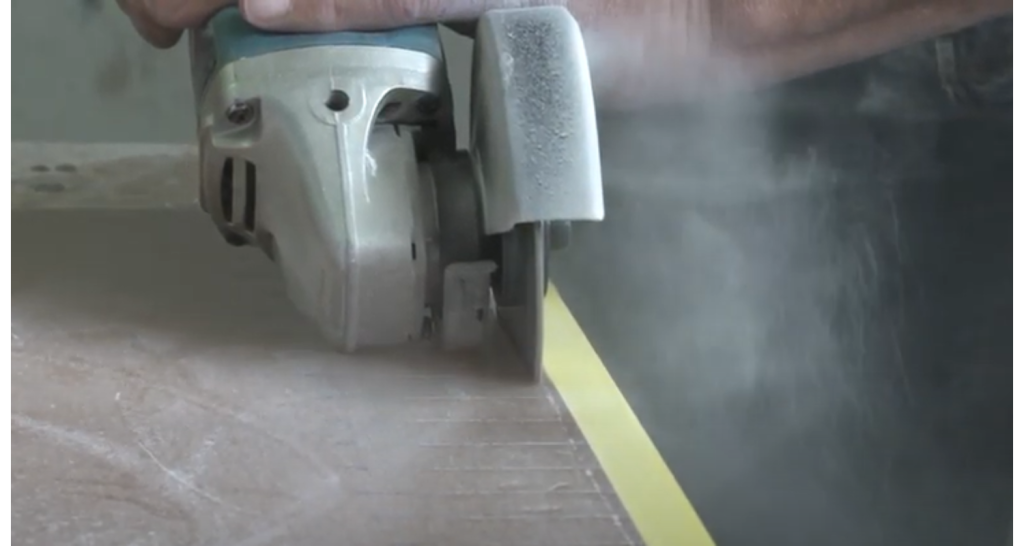

Circular Saw Blades with Anti-Kickback Design

Why it’s great : Circular saw blades designed for fiberglass provide clean, straight cuts with minimal dust.

Best for: Cutting large sheets of fiberglass insulation.

Popular brands: Freud, Irwin, and Makita.

Insulation Knives with Hook Blades

Why it’s great: Insulation knives are specifically designed for cutting fiberglass and other insulation materials.

Best for: Quick, on-site cuts.

Popular brands: Husky, Lenox, and Klein Tools.

Key Features to Look for in a Fiberglass Cutting Blade

When selecting the best blade for cutting fiberglass insulation, consider the following features:

- Sharpness: A sharp blade ensures clean cuts and reduces the risk of fraying.

- Durability: Look for blades made from high-quality materials like carbide or diamond.

- Anti-Clog Design: Blades with anti-clog features prevent fiberglass particles from sticking, ensuring smooth operation.

- Safety Features: Blades with dust-reduction technology minimize airborne particles, protecting your health.

- Compatibility: Ensure the blade is compatible with your cutting tool (e.g., circular saw, reciprocating saw, or utility knife).

How to Cut Fiberglass Insulation Safely and Efficiently

Using the best blade for cutting fiberglass insulation is only part of the equation. Follow these steps for safe and efficient cutting:

Wear Protective Gear: Use gloves, safety goggles, and a respirator to protect yourself from fiberglass particles.

Measure and Mark: Use a tape measure and marker to outline the area you need to cut.

Choose the Right Tool: Select a tool that matches your blade (e.g., utility knife, reciprocating saw, or rotary tool).

Cut Slowly and Steadily: Apply even pressure to avoid tearing the insulation.

Dispose of Waste Properly: Collect and dispose of fiberglass scraps in a sealed bag to prevent airborne particles.

FAQs About Cutting Fiberglass Insulation

- Can I use a regular saw blade to cut fiberglass insulation?

While you can use a regular saw blade, it’s not recommended. Fiberglass-specific blades are designed to minimize dust and provide cleaner cuts. - What is the best tool for cutting fiberglass insulation?

The best tool depends on the project. For small cuts, a utility knife works well. For larger projects, a reciprocating saw or circular saw is more efficient. - How do I reduce dust when cutting fiberglass insulation?

Use a blade with dust-reduction technology and work in a well-ventilated area. Wearing a respirator is also essential. - Can I reuse fiberglass cutting blades?

Yes, but ensure the blade is still sharp and in good condition. Dull blades can cause uneven cuts and increase dust.

Why Invest in the Best Blade for Cutting Fiberglass Insulation?

Investing in the best blade for cutting fiberglass insulation offers several benefits:

Precision: Achieve clean, accurate cuts for a professional finish.

Efficiency: Save time and effort with blades designed for fiberglass.

Safety: Minimize health risks by reducing airborne particles.

Cost-Effectiveness: Durable blades last longer, reducing replacement costs.

Conclusion

Choosing the best blade for cutting fiberglass insulation is essential for achieving clean, precise cuts while ensuring safety and efficiency. Whether you’re working on a small DIY project or a large-scale construction job, the right blade can make all the difference. From carbide-tipped utility knives to reciprocating saw blades, there’s a perfect tool for every need. By following the tips and recommendations in this guide, you’ll be well-equipped to tackle any fiberglass insulation project with confidence.