If you’re looking to perfect your fiberglass cutting technique, you’ve come to the right place. Fiberglass is a versatile and widely used material in many industries, from boatbuilding to construction. It’s known for its strength, durability, and lightweight properties. However, cutting fiberglass can be a tricky task, as it requires precision and the right tools to do it correctly. In this blog post, we’ll take a deep dive into the world of fiberglass cutting and provide you with essential tips and tricks to make your cutting job easier. From how to choose the right cutting tools to the proper cutting techniques, we’ll cover every aspect of fiberglass cutting to help you achieve the perfect finish for your project. Whether you’re a novice or an experienced professional, our tips will help you improve your skills and take your fiberglass cutting to the next level. We’ll also touch on safety precautions you should take when working with fiberglass and respiratory protection you should use, ensuring your safety when handling the material. So strap in and

1. Use a sharp blade.

When it comes to fiberglass cutting technique, using a sharp blade is crucial. A dull blade often leads to fibrous edges and fraying, which can lead to a less-than-desirable finished product. Using a sharp blade ensures clean cuts, reduces the risk of injury, and ultimately saves time in the long run. It’s important to regularly check and replace blades as needed to maintain cleanliness and precision in the cuts. When working with fiberglass material, using a sharp blade is a simple yet effective way to ensure a professional and high-quality result.

2. Mark the cut accurately.

When it comes to fiberglass cutting, accuracy is essential to achieve the desired results. A crucial step in the process is to mark the cut accurately on the material. Begin by measuring the fiberglass using a ruler or measuring tape. Then, use a marker or sharpie to make a clear and accurate line along the measured area. It is essential to ensure that the line is straight and clear, as this will serve as our guide in cutting the fiberglass later. Any mistakes done at this stage will result in wasted resources and time. Therefore, it is essential to take this step seriously and make sure that the line is accurate to set yourself up for a successful fiberglass cutting process.

3. Protect yourself from fiberglass dust.

Fiberglass is a widely used material in the construction industry due to its strength and durability. However, cutting fiberglass can produce hazardous dust which can damage your skin, eyes, and respiratory system if proper precautions are not taken. Therefore, it is crucial to protect yourself from fiberglass dust when cutting the material. The following are steps to protect yourself from fiberglass dust:

1. Wear protective clothing: Before you start cutting fiberglass, put on protective clothing such as a long-sleeved shirt, pants, gloves, and a respirator. The clothes should be snug to prevent fiberglass dust from finding its way inside.

2. Work in a well-ventilated area: Make sure you are working in an area that is well-ventilated. This will allow the fiberglass dust to disperse into the air and prevent it from settling on your skin and clothes.

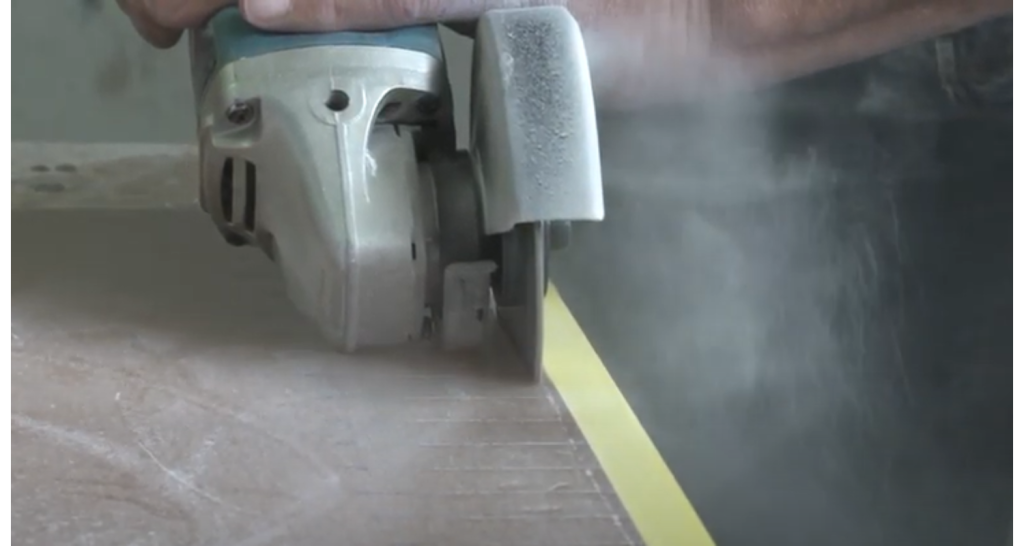

3. Use proper cutting tools: When cutting fiberglass, make sure to use the right cutting tools, such as a circular saw with a fiberglass cutting blade. This will produce less dust than other cutting tools.

By following these steps, you can protect yourself from fiberglass dust and ensure safe cutting of the material.

4. Cut with a steady hand.

When working with fiberglass, it is essential to use proper cutting techniques to achieve precise and even cuts. One of the most important aspects of fiberglass cutting technique is to cut with a steady hand. By keeping the hand steady, the cutting tool can be guided accurately through the fiberglass material. This can help ensure clean and even cuts, and prevent the material from fraying, splintering, or cracking. In order to maintain a steady hand, it’s important to have a comfortable and stable grip on the cutting tool, as well as positioning the material securely to prevent it from shifting during the cutting process. Following the guideline of cutting with a steady hand can be a valuable tool in producing quality fiberglass products.

5. Finish the edges carefully.

When working with fiberglass, finishing the edges carefully is an important step in achieving a professional-looking result. The edges of a fiberglass piece, if not properly finished, are prone to fraying and breaking, which can weaken the overall structure. One technique to ensure clean and neat edges is to use a rotatory tool with a sanding attachment. Another useful approach is to use a fiberglass edge sealer, which can strengthen the edge and prevent it from cracking or splitting. It is also important to wear proper safety gear, such as gloves and safety glasses, when handling fiberglass and using tools to finish the edges. By taking the time to finish edges carefully, you can ensure a strong and durable finished product.

To conclude, fiberglass cutting technique is a vital skill for anyone working with fiberglass materials. The process can be challenging and require precision and attention to detail, but once mastered, it can greatly increase the effectiveness and efficiency of any fiberglass work. With proper safety equipment and tools, this technique can be accomplished with ease and provide excellent results. Whether you are working on a hobby or professional project, mastering this technique can help take your fiberglass work to the next level.